Striving

for Quality.

クオリティの追求

我々はお客様のイメージを的確に再現するために、現場へ足を運ぶことを大切にしています。口頭でなければ伝わらないような細部のこだわりのニュアンスや雰囲気、お客様の想いと共に現場と共有し物作りに取り組んでいます。

Now Loading

我々はお客様のイメージを的確に再現するために、現場へ足を運ぶことを大切にしています。口頭でなければ伝わらないような細部のこだわりのニュアンスや雰囲気、お客様の想いと共に現場と共有し物作りに取り組んでいます。

In order to accurately reproduce the client's image, we place great importance on visiting the site. We work to create products by sharing with our clients the nuances of detail and atmosphere that would otherwise be difficult to convey verbally, as well as their thoughts and feelings.

Many of the materials we handle are subject to post-processing. Starting from one wash, BIO, stone wash, bleach, USED, product dyeing, etc... In the planning stage, we select fabrics by imagining what they will look like after processing. Some fabrics gain volume by washing, while others lose their elasticity. With our long years of experience and knowledge, we will propose appropriate materials according to your image.

Special materials can also be made to order, so please contact us for more information.

We can also handle raising, coating, water repellency, and other special processing of fabrics.

We have in-house AGMS CAD. Starting with the master pattern, we perform shrinkage rate adjustment, pattern modification, and grading. Even with the same material, the shrinkage rate will vary depending on the post-processing. A lot of knowledge and experience are required to deal with each of them. We have tie-ups with highly skilled pattern companies outside the company, and we can also accept requests for patterns only.

A lot of garment materials are used for one product.

Some are metal buttons and some are resin buttons with thread.

We will promptly select materials that match your image and that can withstand processing.We can also help you with original imprinting, etc.

Photography cooperation: Watanabe Sewing Cabinet Co. Cabinet is a company raised in Kojima, a town of jeans.

Its greatest strength is items made of denim material.

The company has a wide variety of tie-ups, from jeans factories that show particular attention to detail to factories capable of mass production, all of which are highly skilled.

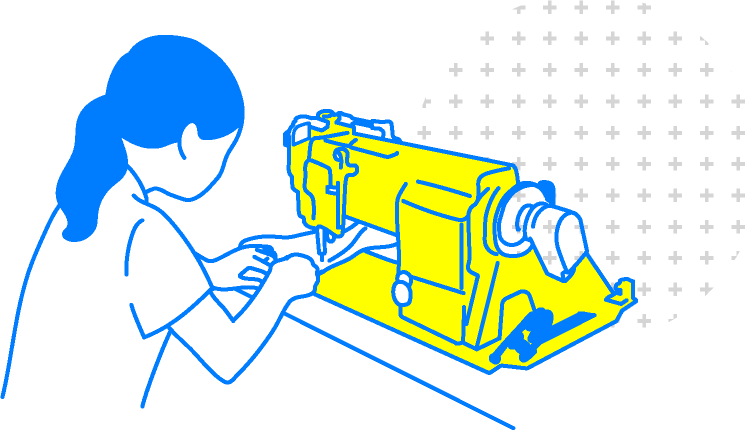

Every genre cannot be shaped without understanding the particulars of the specifications. Starting with factories that sell powerful sewing with Union Special (industrial sewing machine) to reproduce good old American jeans, we have factories that specialize in work and military goods, factories for bag accessories, and now factories (Akita, Aomori) that specialize in sewing beautiful jackets and slacks, and even cut-and-sew factories. We are able to meet a wide range of requests.

A wide variety of secondary processing is available. Embroidery and printing that can be handled using a variety of techniques. Washing process controls the expression and texture of products. In particular, we are proud to say that our washing technology is among the best in Japan. We offer a wide range of processing services, from machine processing to handwork by craftsmen.

In addition to silk screen printing, which is a common method, we can also handle inkjet, transfer, flocking, and die-cut printing. Please consult with us for anything from a single point to large patterns.

We offer a variety of embroidery techniques to match the atmosphere of the item, such as “furi” embroidery, which expresses patterns and characters with a swing of thread, “tatami” embroidery, which uses fine stitches, and chain embroidery and sagara embroidery, which are often seen in American casual wear.

FinishFinish shipping, press working, inspection, needle inspection, and delivery.

Inspection, needle inspection, and deliveryFinal inspection, finishing, and needle inspection are performed.

Whether or not a product is ready for the market is determined by the final pressing process.

Here, too, we iron and press in an appropriate manner, paying close attention to the image of the product.

Depending on the product, it may be possible to leave the unwashed texture without pressing.

有限会社 じいんず工房大方